Researchers and engineers at the 3D Printing Lab are collaborating with clinicians and specialists at AKU to conduct groundbreaking research in efforts to improve access to quality health care and education for vulnerable populations in resource-constrained areas. By harnessing the capabilities of 3D printing technology, AKU dHRC aims to revolutionize the healthcare landscape across low- and middle-income (LMICs) countries by providing innovative and customizable solutions to improve health care for all.

More recently, AKU has received regulatory approval to produce 3D printed implants.

One significant advantage of 3D printing is its ability to generate customized and complex medical devices, such as prosthetics and implants, tailored to an individual's specific anatomy. 3D printing technology has allowed AKUH to make precision medicine more accessible by reducing costs. It has enabled the development of customizable solutions to address the specific needs of different individuals, ensuring equal access to health care for all.

Customized dental implants, dental crowns and dental bridges are currently being 3D printed. 3D-printing such items as opposed to manual production reduces costs for patients and enhances precision. Clinical trials assessing the feasibility and potential clinical application of 3D printed dental crowns are planned for launch in July 2024.

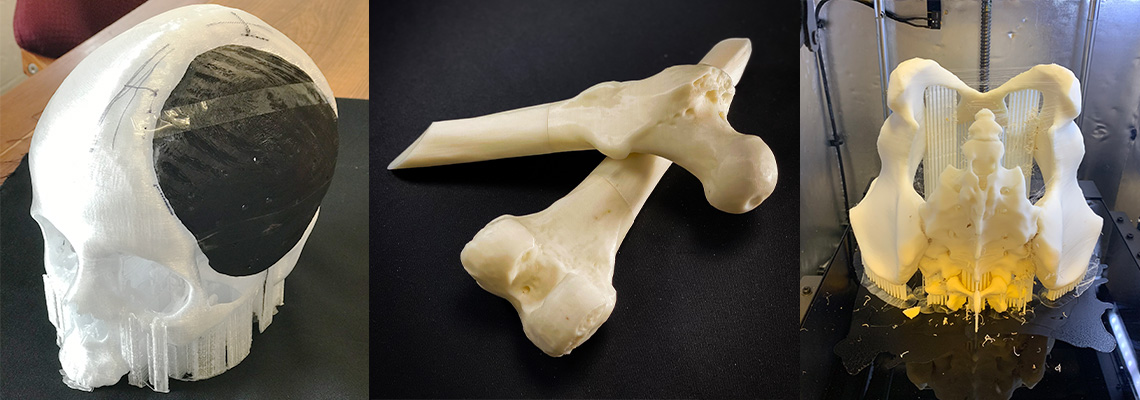

Researchers and engineers, in collaboration with the Department of Surgery, are pioneering the use of 3D printed craniotomy implants, in order to improve outcomes in low- and middle-income countries (LMICs). Traditional cranioplasty methods, using prefabricated implants or sculpted acrylic, often face limitations in resource-constrained settings. 3D printing offers a customizable solution, tailored to each patient's specific defect. This can potentially reduce the need for multiple surgeries and ensure a better fit, leading to improved surgical outcomes, shorter hospital stays, and reduced overall healthcare costs – all critical factors in LMICs with limited medical resources. Additionally, 3D printing technology has proven to be more affordable than traditional methods, making this personalized surgical approach more accessible to patients across Pakistan.

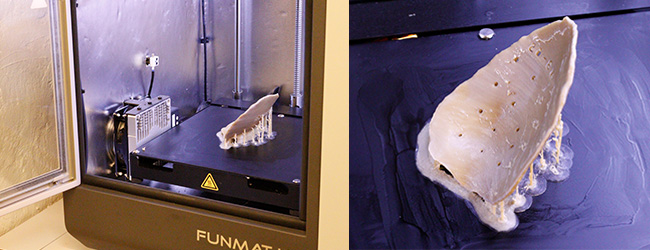

The Center’s 3D printing initiative to develop cost-effective educational training models is helping bridge the gap between theory and practical application. Limited financial resources make it difficult for educational institutions in LMICs to provide hands-on learning experiences to their students. 3D printing technology enables the development of affordable training models, which can be designed and fabricated using readily available materials, allowing students to visualize complex concepts and enhance their understanding. The Center has been printing various training models for educational purposes, including a 3D-printed cranioplasty models; a dental x-ray exposure assessment mannequin; a dental training model for root canal procedures; and an ophthalmology training model. Additionally, training models for the evaluation of pelvic and femur bones have also been developed for practical learning in orthopedics.